Our Clients and References

We manufacture individual parts, prototypes, and series components for many industries, small, medium-sized and global enterprises, as well as research institutions

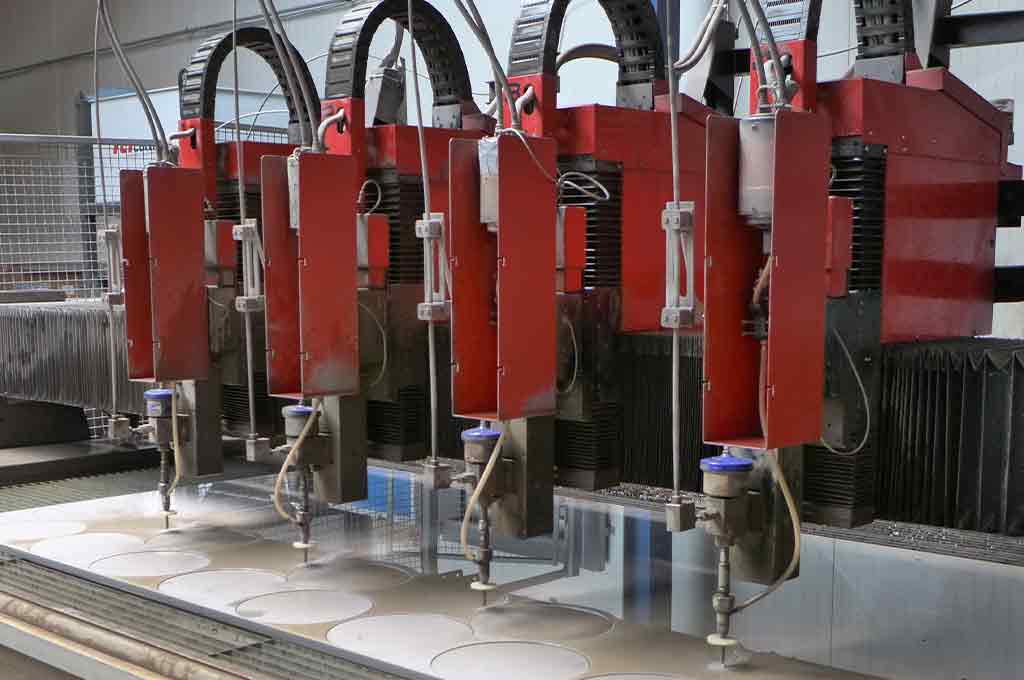

2D Waterjet Cutting

Waterjet Cutting for Components up to 10,000 x 4,000 mm

Up to six cutting heads per system ensure cost-effective production, whether it’s for single part or large-scale series production. Our modern CNC control and programming systems guarantee high precision in the shape of your components. Additionally, our systems offer potential for rationalization through:

- 4 individually controllable cutting heads

- Pipe module

- 2 drilling units for starter hole drilling

- Abrasive and pure water cutting

High cutting speeds and maximum precision

Environmentally friendly and economical alternative

- You are involved in toolmaking, mechanical engineering, plant construction, automotive manufacturing, facade construction, aerospace, metalworking industry, or a similar sector and are looking for an alternative to thermal cutting or turning and milling?

- The technology is characterized by high cutting speeds and a precision of up to ± 0.05mm. This precision allows for narrow kerfs and thereby excellent material utilization.

The following two cutting processes are distinguished:

With pressure from 4,000 – 6,000 bar

Abrasive: for metals and hard materials – An abrasive medium is added to the cutting jet, allowing for the cutting of components in great material thickness.

Pure water: for seals, foam, and plastics – Very fine cutting jet and no contamination of the components.

With water pressure up to 6,000 bar, an extremely precise cutting jet is generated. This can cut almost all materials in material thicknesses of over 300mm without deformation in the cut area. There are no thermal effects in the materials, preventing stresses and distortions. The process is suitable for workpieces made of all metals, plastics, carbon, rubber, sandwich panels, and many other materials.

For example, do you need weld preparation on your components? Then our 3D water jet cutting or our mechanical post-processing might be of interest to you.